How industry can make battery recycling more sustainable in Nigeria

The rise of decentralised renewable energy (DRE) systems in Africa has brought about an increased deployment of batteries, particularly lead-acid batteries, which are the most used battery-type on the continent. As production volumes soar, the issue of sustainable battery recycling has come to the forefront. Today, project developers face a significant dilemma: where to send used batteries to ensure environmentally sound recycling. Unfortunately, most recycling plants fail to meet environmentally sound recycling standards, leading to severe lead exposure. Globally, one in three children has elevated blood lead levels, resulting in lifelong health consequences[1].

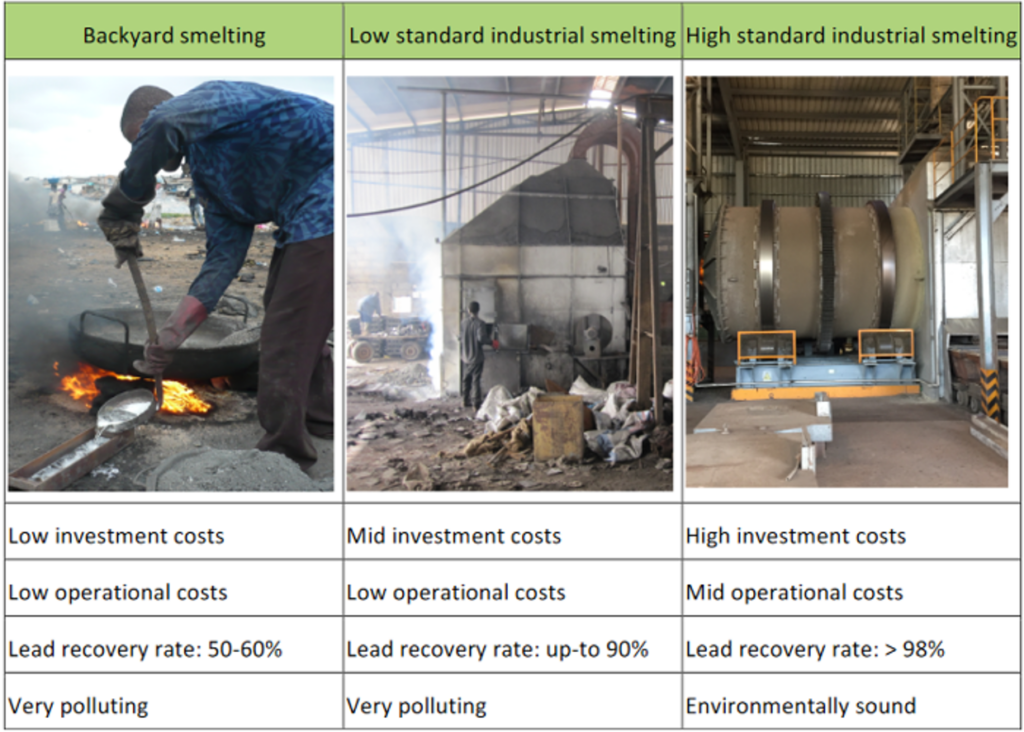

Moreover, the economic impact of lead exposure in Nigeria is staggering, costing up to $16.2 billion annually, or 3.94% of the GDP[2]. This problem is not unique to Nigeria though; prominent pollution cases are also reported in Senegal and Kenya. The root cause of pollution in lead-acid battery recycling lies in unregulated markets where low-standard industrial smelting emerges as a highly profitable business since environmental costs are ignored. These operations, characterised by low investment and operational costs, recover only 50-60% of lead and are highly polluting. In contrast, high-standard industrial smelting (environmentally sound recycling), although more costly, achieves a lead recovery rate of over 98% representing only an 8% increase in recovery rate when compared to low standard industrial smelting.

Different types of smelting (Source: Oeko-Institut):

ProBaMet: A Collaborative Approach to Reforming Battery Recycling

Transforming the battery recycling sector in Nigeria requires a multifaceted approach. The Partnership for Responsible Battery and Metal Recycling (ProBaMet), launched by Oeko-Institut, the Alliance for Rural Electrification (ARE), SRADev Nigeria, and Platform Blei (an initiative of WirtschaftsVereinigung Metalle), aims to support local regulators and stakeholders address this issue. Funded by the Federal Ministry for Economic Cooperation and Development (BMZ) and supported by Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, the project seeks to support the modernisation of the recycling sector in the country in a sustainable direction.

ProBaMet’s strategy involves three key components. The Oeko-Institut and its project partners are providing knowledge on environmental protection and occupational safety for recycling plants and training plant managers to improve environmental performance and plant safety. In addition, the partners are supporting Nigerian regulatory authorities enforce and monitor binding standards for environmental protection and occupational health and safety. Finally, the project seeks to create opportunities for business linkages for recyclers who recycle used lead-acid batteries (ULABs) in an environmentally sound manner.

Since its launch in early 2024, ProBaMet has focused on building strong partnerships with local stakeholders. In Ogun State, the project organised a series of workshops and conducted visits to six battery recycling plants in the area. Five of these accredited plants were found to be highly polluting, however the sixth facility visited showed a high standard of production and environmental protection considerations. As a result, the project partners together with the Nigerian federal Ministry for Environment, Nigerian National Environmental Standards and Regulations Enforcement Agency (NESREA) and other Nigerian stakeholders have issued recommendations for necessary improvements. Additionally, the ProBaMet project was introduced at the ARE Energy Access Investment Forum 2024 in Lagos, where it garnered significant interest from the DRE sector. The ProBaMet team will in the month of September engage with regulators and recyclers in Nigeria for in-depth capacity building training sessions in Lagos.

Currently, the project is focused on developing circularity guidelines to promote standards for battery management in Nigeria. These guidelines will allow DRE sector companies to commit to working with recycling plants that adhere to higher standards. Without a steady supply of ULABs, environmentally sound recyclers will have to discontinue business operations due to significantly higher production costs compared to low-standard industrial recyclers. This commitment will enable the DRE sector to influence the shaping of battery recycling practices, making them more sustainable. ARE is spearheading the creation of these guidelines for end-of-life battery management, which the sector will endorse to ensure safe recycling practices. Industry stakeholders are still able to provide feedback by downloading the guidelines.

In conclusion, it is crucial to send a strong message to suppliers, project developers, and policymakers that standards and improvement processes are vital for battery recycling. By raising the sector’s standards, not only will it create green jobs, but it will also enhance the safety and livelihoods of the local population. Sustainable battery recycling is not just an environmental necessity but also a pathway to a healthier and more prosperous future for Nigeria.

[1] UNICEF, 2020: https://www.unicefusa.org/stories/1-3-children-worldwide-have-lead-poisoning#:~:text=The%20report’s%20researchers%20concluded%20that,levels%20live%20in%20South%20Asia.

[2] Economic costs of childhood lead exposure in low- and middle-income countries, 2013: https://ehp.niehs.nih.gov/doi/10.1289/ehp.1206424